본문

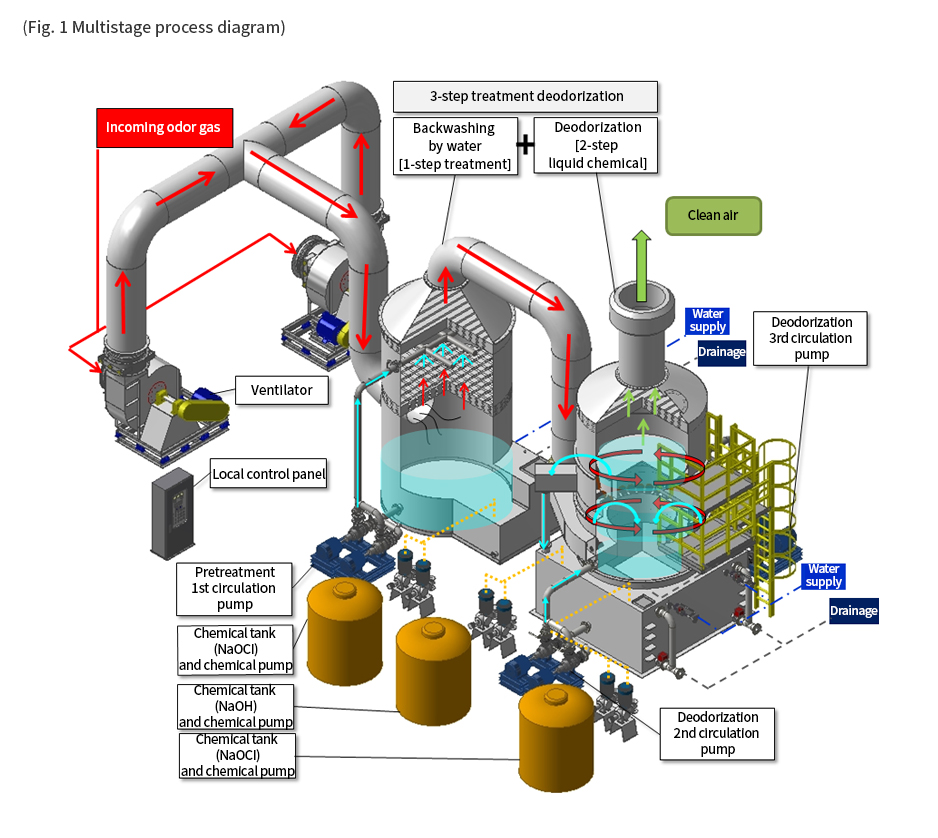

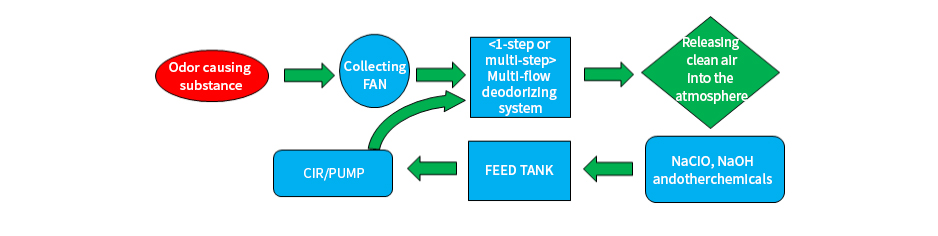

The Multi-flow Deodorizing System cleans liquid chemicals by inhaling the gas inside the liquid and then spraying it through the gas spraying device inside the liquid to increase the specific surface area of the gas while expanding the contact area between the gas and liquid. Thus, our technology effectively removes bad smelling gases, and it is a system that allows for the selective installation of multi-step cleaning and a 2-step or higher cleaning process.

The odor gas collected with the FAN from the odor causing substance is sent to the reaction part (bottom), and then the aqueous solution from the 1st circulating water tank is released to the reaction part (bottom) so that the gas spraying device submerged under the chemical solvent sprays the odor, and as a result the gas and liquid come into contact with each other and collide in different speeds and directions.After the primary cleaning of the reaction part (bottom), the remaining odor is transferred to another reaction part (top). The aqueous solution from the 2nd circulating water tank is released to the reaction part (top) so that the gas spraying device submerged under the chemical solvent sprays the odor, and as a result the gas and liquid come into contact with each other and collide in different speeds and directions.The odor that is cleaned for the second time at the reaction part (bottom) passes the gas/liquid separating unit on the top, and the separated gas is released into the atmosphere.

The gas spraying device is comprised of the gas spraying nozzle and spraying nozzle housing; generation and annihilation of a large amount of fine bubbles of the odor gas are processed, and there is a high contact efficiency between the odor gas and aqueous solution.Summing up, the system features a mechanism that has maximized the specific surface area.

- Stable due to the constant spraying speed of the gas spraying nozzle and the constant pressure of the deodorizing system

- The screw type gas spraying nozzle provides easy assembling and disassembling, thus allowing easy maintenance

- The reduced size of the body compared to that of the existing deodorizing system guarantees lesser demand on the area

- Large specific surface area of the odor sprayed from the gas spraying nozzle, high odor reduction efficiency

- Does not get affected by the surrounding environment and changes of the season (temperature and humidity)

- Simple principle of the system, low possibility of breakdown, and low maintenance expenses

- Preventing afall in the fluid running speed by minimizing the friction force of the purifyingsolution that rotates and moves at the same time throughforming multiple dimples (circular grooves)in the inner walls.

- Suppressing the gas-liquid flowgains as much laminar as possible, and maximizes the efficiency through inducing the turbulent flow.

- Training programs for the safety management and maintenance of the deodorization system and issuance of guidebooks

- Regular inspection for preventing thedamage of equipment

- Efficientfollow-up service through establishing an easy, quick, and convenient wire network

- Maintaining optimal conditions for minimizing the maintenance expenses

- Sewage treatment plant, sewage sludge drying facility, and village sewage

- Human excreta treatment plant, livestock excretion treatment plant, food waste treatment plant

- Wastewater treatment facilities of an industrial complex and agricultural industrial complex

- Landfill sites and harmful gas discharging facilities

- Other odor causing plants, leachate treatmentplants,etc.

- Suitability according to the different seasons and rapid changes in odor concentrationatdifferenttimes

- Efficiency depending on the changes in atmospheric temperature and humidity

- Maintenance and operation convenience

- Appropriateness of the site area according to the deodorization capacity

- Durability and economic feasibility of the deodorization equipment